G Systems developed a high-speed streaming measurement system for capturing pressure waves generated by explosions during structural blast testing.

G Systems developed a high-speed streaming measurement system for capturing pressure waves generated by explosions during structural blast testing.

A G Systems customer needed a solution that would record measurements in a blast zone to document the pressure waves during structural testing. Requirements included the ability to collect 16 channels at 1 million samples per second simultaneously. They also needed to trigger high-speed cameras with configurable delays to record video documentation of the explosion. In this blast, test environment safety is a critical consideration.

To develop the needed system G Systems used pressure sensors that can survive the over-pressure from a 1200 lb explosion. These signals are sent to a nearby CompactRIO data acquisition system to simultaneously measure and record the signals. All set-up and configuration is accomplished remotely, through a private LAN connection, at least 1000 feet away to meet personnel safety standards. The data is saved as a TDMS file on a SD memory card or USB drive while real-time data is displayed remotely for the operator’s safety.

Fortis Testing in Lubbock, TX, contacted G Systems to build a blast test system. The system needed 16 channels, fast sampling, had to function very close to the blast zone to minimize signal degradation from the sensors, and also be remotely configurable.

G Systems recommended using an 8-slot CompactRIO controller with several high-speed simultaneous data acquisition cards and a custom designed FPGA program as the backbone of the system. Remote access is accomplished by one of two built in Ethernet ports on the controller. The triggering of several remote cameras happens with a fast digital I/O card from NI. The rugged CompactRIO design – along with a protective enclosure – enables the system to survive in close proximity to the blast zone.

The measurement system consists of up to 16 blast wave sensors, a multichannel sensor biasing and buffering box, a high-performance CompactRIO controller, four 4-channel analog input cards, one 4-channel digital input/output card, a power source, and a remote PC connected by LAN over coax.

The blast wave sensors are mounted in the danger zone at appropriate locations to measure the pressure wave according to the customer’s needs. The sensors are biased properly while their high impedance signals are buffered and sent to the CompactRIO DAQ. See Figure 1.

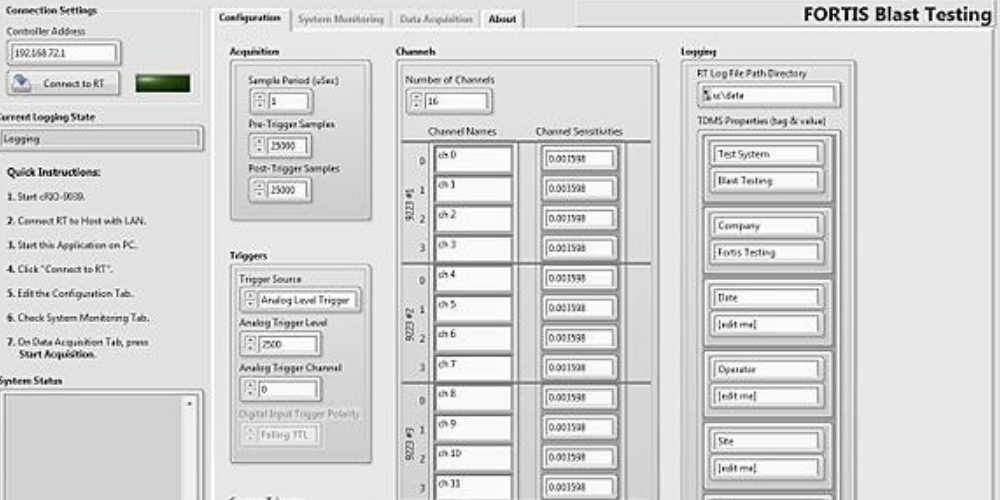

The signals from the sensor buffer are connected to the 16 BNC inputs on the four 4-channel analog input cards. The digitized samples are then routed to the FPGA in the CompactRIO backplane. The FPGA is responsible for the following functions: variable sampling rate up to 1 million per second, number of pre- and post-trigger samples, trigger source and trigger level, cameras’ trigger polarity and pulse width, and cameras’ trigger delay. All these FPGA functions are configurable through the User Interface (UI) shown in Figure 2.

The data from the FPGA is then sent to the CompactRIO controller through first-in-first-out memory management (FIFO). The CompactRIO, running NI’s Linux real-time operating system, is responsible for communicating back to the main UI, monitoring the system and FPGA health, acquiring the data from the FPGA FIFO and logging it to non-volatile memory, and performing a hardware watchdog function to reset the CompactRIO controller in case it stops functioning.

The FPGA must sample simultaneously to meet the customer’s requirements. The analog input card’s user-sampling mode gets the throughput up to 1M samples/second. Another requirement was configurable pre-trigger and post-trigger samples.

G Systems created a constantly acquiring circular buffer in order to provide pre-trigger samples since there is no way to predict when a trigger event will occur. Triggering, being configurable, might come from an analog input channel, a digital input of any polarity, a manual trigger, or simply a free running trigger. Upon triggering, the FPGA sends the data to the CompactRIO controller through a FIFO for the prescribed number of pre and post-trigger samples.

The CompactRIO controller time-stamps and scales the digital samples to engineering units. The samples are written to a TDMS file on either an SD card or USB memory in the CompactRIO controller depending on the operator’s preference. The CompactRIO controller sends the captured sample stream back to the UI over the LAN connection as a verification that the measurement has succeeded.

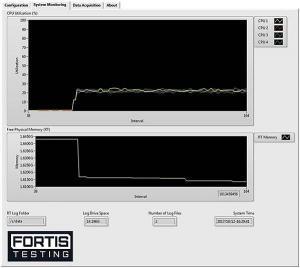

The UI, running on the latest windows operation system, is used to configure and arm the measurement system before the explosion is initiated. Each sensor can have a unique sensitivity assigned in case they are different sensor models. The graphical and recorded data uses the sensor sensitivity to scale the pressure wave readings to the customer’s desired units. The UI monitors the CPU utilization of the four processors and the free memory on the CompactRIO controller. This allows users to gain confidence remotely in the measurement system’s readiness, since this type of testing is destructive. See Figure 3.

Multiple users can save and recall configurations in order to reduce the setup time between different jobs. The CompactRIO controller application automatically blinks a front panel LED at 1 Hz to notify the operator that the program is functioning since there was no UI near the blast zone.

Data is written using a TDMS file format, tagged with all the metadata from the configuration page. The customer, Fortis Testing, is able to examine and analyze the data in Microsoft Excel using the free NI TDM Excel Add-In for Microsoft Excel.

This system records data from four analog input cards, after a configurable trigger condition (analog, digital, manual, or free running), onto an external memory drive for later retrieval. The system is configurable and data results are shown using a remote user terminal application or human machine interface (HMI).

Using their expertise of NI’s embedded FPGA based products along with proven architectures G Systems successfully and quickly developed a system to measure and record blast wave pressures during structural explosion testing that met high speed streaming requirements. The use of ruggedized equipment close to the explosion minimized signal degradation before processing. Confidence before the destructive test was gained by monitoring CPU and memory load remotely. Configurability gave Fortis Testing the needed flexibility to successfully change the measurement strategy as needed to meet variations in their own customers’ requirements.

The best way to begin is by having a conversation with a member of the G Systems teams about your test challenges and the options for helping you solve them.

Based near Dallas, Texas, G Systems is an internationally recognized systems integrator specializing in the modernization of complex systems of all sizes. We are experienced in the design, integration, assembly, production, and maintenance of custom turnkey solutions that support our customers at all phases of their product’s maturity cycle.

NAICS Codes: 541330, 541715, 541511, 334515, 335999, 334519

CAGE Code: 3HPP5

![]()