Like an overdue brake pad inspection, an obsolete system is a problem that can sneak up on you and cost you a lot of time and money to fix. System obsolescence is a big issue, and companies often don’t realize their components and systems are obsolete until it causes a crisis. Understanding the status of your system and components will help you make meaningful changes and upgrades that will help you get more life out of your systems.

Much like worn out brake pads, aging systems will begin to “squeak.” The trick is knowing what to look for. Here are some telltale signs that your system is due for a technology refresh.

Do equipment breakdowns leave you stranded?

Obsolete hardware that is no longer manufactured is extremely difficult to manage when something breaks. What would you do if your system breaks? Do you or your engineers spend hours scouring eBay and used part resellers? Companies with obsolete hardware and software suffer prolonged downtime while they retrofit solutions to existing components with limited support from vendors.

Slow Execution? Lots of Equipment Errors? Hard to Get Support?

Systems moving into obsolescence will begin to generate more failures. Those failures in turn require engineering time to remedy. If this is happening frequently, or if you start having those calls with support where the support engineer on the other end has ‘never heard of that before’, you may be encountering complications from obsolescence. These may seem like nuisance issues, but eventually the situation may arrive when things cannot be fixed or a significant downtime event happens.

Are compatibility issues preventing you from adding new features?

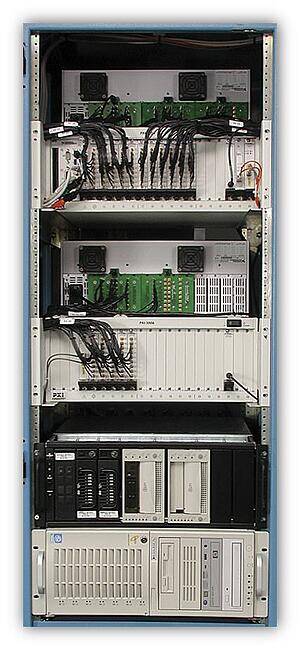

Old operating systems and hardware aren’t often compatible with new hardware. To keep up with testing demands, companies often need increasing capabilities like more channels and the ability to test in increasingly harsh environments, but they get stuck when they are limited to the hardware that an old operating system can manage.

Is your system open to security breaches?

Because of the widening Internet of Things, control systems are more susceptible to cyber-attacks. If you are running on an unsupported platform, like Windows XP, you are even more at risk of experiencing a cyber event. Each month, software companies send out system updates and patches that fix the security issues hackers are exploiting. By keeping your system updated and routinely patching your system, you can protect against the majority of cyber attacks.

The Secret to Immortality

If you answered yes to any of these questions, your test system is showing its age. Obsolescence is a reality that all systems will eventually face. After all, no one’s carrying around that cutting-edge iPhone 1 anymore, are they? While you have to buy a whole new iPhone, your test system is more flexible than that. Managing obsolescence is about solving small problems before they become big problems.

A tech refresh gives you the opportunity to evaluate your overall testing needs. To make sure the changes you implement will help future-proof your system, follow these steps:

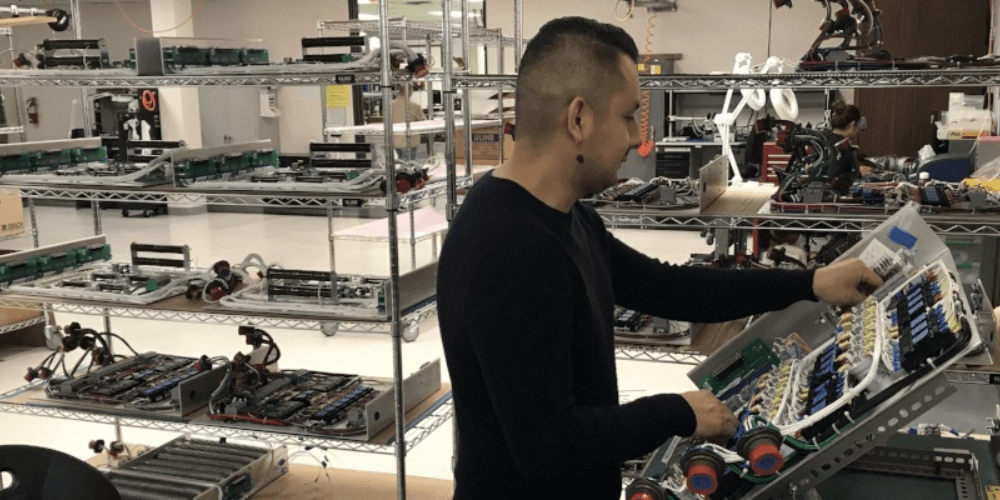

1. Inventory hardware and drivers

2. Identify obsolete hardware components

3. Assess risks of continued use

4. Assess risks/benefits of replacing obsolete components

5. Remedy problems with new drivers or replacement hardware

6. Add new components to meet additional needs

When you identify and implement changes, consider these enhancements to your overall system:

- Upgrade your software: Upgrade platforms from unsupported software to new supported and more secure versions

- Modernizing your existing hardware: Expand capabilities with better data acquisition and test components

- Future-proofing new systems: Design modular test systems with growth and driver updates in mind. For example, modularizing driver calls in a LabVIEW class structure will allow software to be readily upgraded to support new drivers and new hardware in the future.

In many cases, a full tech refresh is not the only solution. Sometimes technology insertion can extend the lifespan of a test system simply by replacing an aged subsystem in such a way that the brand-new subsystem has the same form/fit/function as the module it replaced. This can be less expensive than a full tech refresh while minimizing the overall impact of the changes by leaving still-working components in place.

Performing a tech refresh can solve many problems your team may be facing due to obsolete hardware and software. Examine your test system today for the signs of obsolescence: downtime, little to no support, holes in test coverage, and strained compatibility requirements. So, are your brakes squeaking?

Download our Complete Guide to Managing Obsolescence to learn more about how to identify obsolescence issues early and manage them once they are identified.