The new solution supports numerous production lines across multiple locations. Watch the video.

G Systems recently debuted an end-of-line test demo created for customers who manage numerous production lines across multiple locations. Our solution can help companies become aware of potential manufacturing line problems before they become major catastrophes.

Introduction

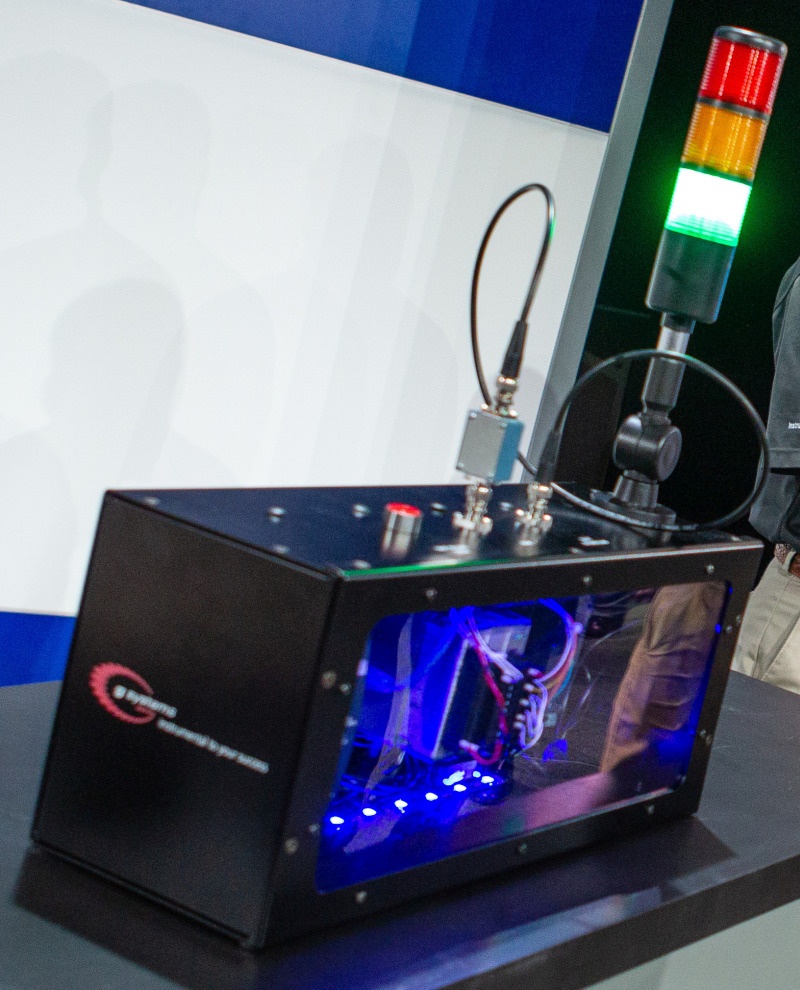

Our new demo is a small example of an end of run tester. The demo uses NI SystemLink in conjunction with a cRIO for remote management and system monitoring of multiple testers. The demo was recently featured in a keynote session at NIWeek 2018.

Dashboards

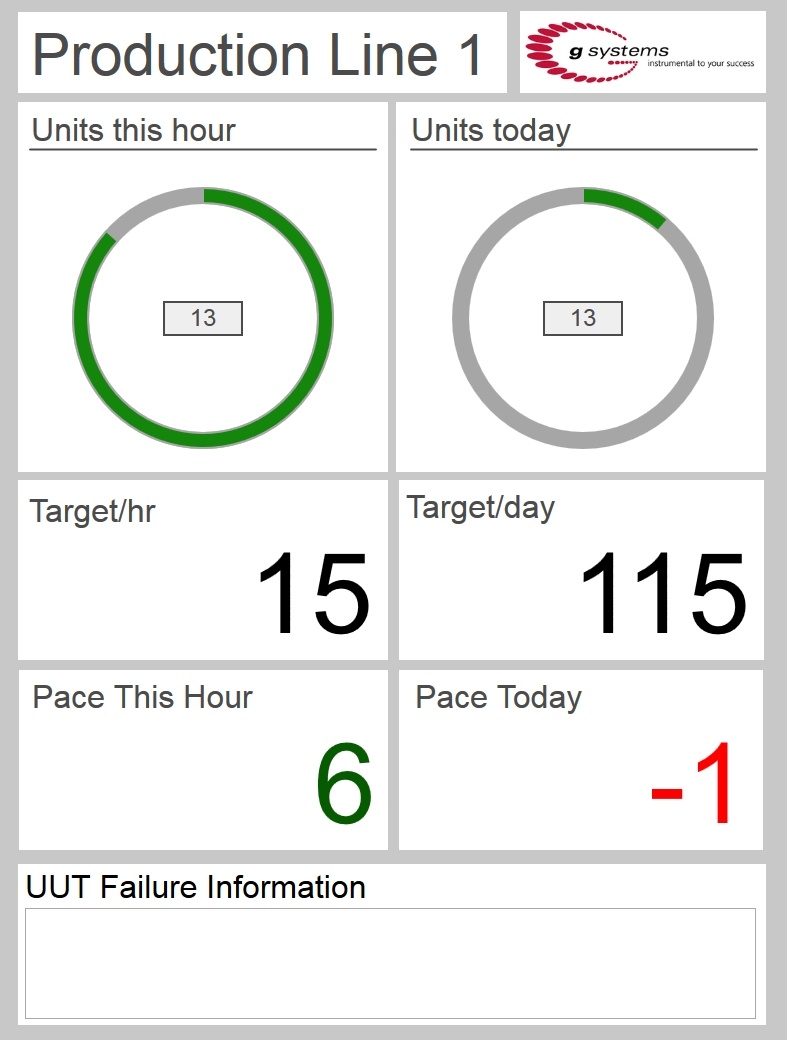

The demo includes three custom dashboards.

Line Status Dashboard: This dashboard is designed to be displayed over a production line and shows production metrics for the day including goals and information on whether or not production is on pace to meet the goals.

Manager Overview Dashboard: This dashboard gives a manager a view of all of the lines as a whole and allows them to set production goals. The manager is presented with statistics like the number of units passed on a line in the last hour and the First Pass Yield (FPY) of each operating line.

Mobile Dashboard: This dashboard is specifically designed to be viewed on a smart phone or tablet computer, allowing the user to get a quick view of the health of the line and most recent problems encountered. Mobile dashboards do not require any special software or apps to run.

Alarms and Notifications

SystemLink has well-developed handling for alarms and notifications. Alarms can be configured based on variables reported to SystemLink from software installed on the demo by G Systems. The alarm system monitors things like CPU usage, available hard drive space, and production metrics like First Pass Yield and number of units passed. When an alarm occurs, a notification strategy is executed to ensure that the proper level of response occurs.

For example, if log files are starting to fill up the hard drive, this will require attention from someone in charge of maintaining and archiving these logs, but it is not an emergency. In this case a simple email notification would suffice, explaining that the storage space will need maintained soon.

On the other hand, suppose the line has gone down. This is an emergency situation and is likely best handled by sending out emails to several parties, as well as text messages in order to ensure an immediate response.

While SystemLink is capable of monitoring tags in order to enact alarms, G Systems has taken this feature a level further by doing post-processing on tags and generating calculated tags in order to predict outages before they occur. While getting a text message warning you that the line has gone down and needs attention is good, it’s even better when the system is able to predict this is about to happen, bringing attention to developing problems before they cause full work stoppage.

Other Important Benefits

Because SystemLink alarms and post-processing of alarms is handled outside of actual tester code, adjustments to post-processing and SystemLink alarms and dashboards can be made without any risk to active testers on the factory floor.

The Remote Deployment utility tracks which versions of test software are installed on each client tester. This gives confidence that every tester is running the same codebase and makes it easy to quickly check with testers are running beta releases of code. This feature also makes it easy to very quickly roll back to known good versions of code if a problem develops in a release candidate, reducing risk and reducing downtime.

How G Systems is in a Unique Position to Help

G Systems is one of only two NI SystemLink Lead Partners. G Systems has proven expertise designing, developing, and assembling ATEs. Now G Systems also includes SystemLink in its production line ATEs. This includes new ATE hardware and software, as well as upgrading existing ATE software. Development can include dashboards, alarms, post-processing for custom alarms, and implementation of notification strategies.

G Systems was also recently appointed an NI Partner Migration Services Program provider. One of only ten NI Alliance Partners currently chosen as program providers, G Systems is among those distinguished by NI for our expertise and ability to migrate and upgrade applications.

Learn more about how G Systems is qualified to provide your test system — including hardware and software — with a technology refresh, in our blog, Is Obsolete Hardware and Software Destroying Your Productivity?

Download our Complete Guide to Managing Obsolescence to learn more about how to identify obsolescence issues early and manage them once they are identified.

Product and company names listed are trademarks or trade names of their respective companies.

A National Instruments Alliance Partner is a business entity independent from National Instruments and has no agency, partnership or joint-venture relationship with National Instruments.