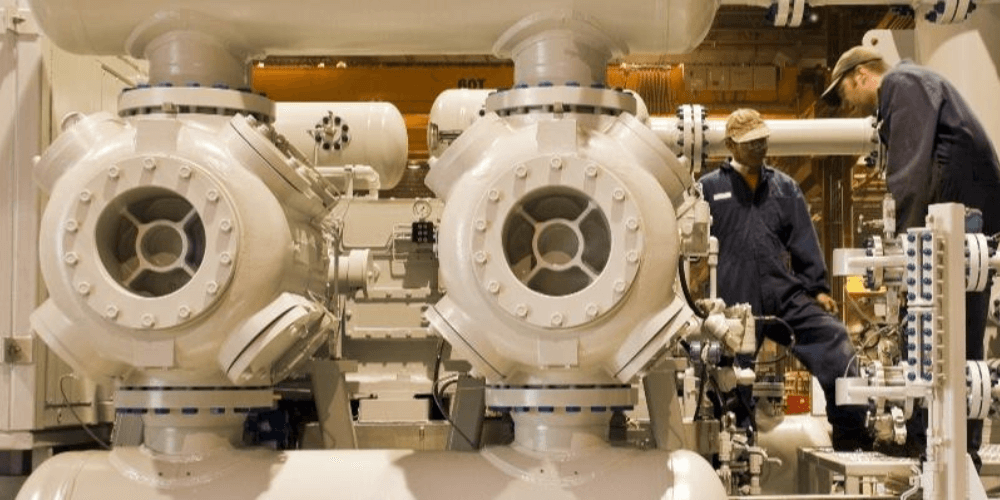

In the natural gas pipeline industry, testing compressor efficiency is essential. With the data collected from this testing, engineers can determine how engines at various sites need to be adjusted to maximize efficiency.

Because the data acquisition (DAQ) systems used to gather this data are expensive to develop, our customer was frequently shipping a single DAQ system between sites throughout the United States as needed. The large size and weight of the system was making this practice increasingly expensive and difficult to manage.

To address these issues, the company hired G Systems to design a new portable DAQ system. They were looking for a system that was more cost effective, light weight, and rugged, so we selected the NI CompactRIO platform as the basis of the DAQ system. Using this compact hardware platform allowed us to easily reduce the size and weight of the system. The ruggedness and small footprint of this design naturally allows for the system to be shipped to test sites via common carriers, such as UPS, without special handling fees.

Additionally, since CompactRIO is an FPGA-based platform, we could easily modify the complex digital triggering and synchronization of the DAQ system to better meet our client’s testing needs. And, by using LabVIEW FPGA software to control the system, we provided an intuitive way to manage the challenging real-time timing schemes required by our customer. Finally, LabVIEW FPGA also aided in the debugging of timing-related issues since the nature of dataflow programming allows the programmer to both see what’s happening at a low level and have complete control of the outputs.

By using CompactRIO hardware and LabVIEW FPGA software, we developed a lightweight, portable test system that met all our client’s requirements, decreased development and debugging time, and provided increased ease-of-use, improved reliability, and cost savings during shipping.

For more information on this application, read the full case study.