It’s no secret that standardizing test equipment and methodologies between your engineering and production test departments will improve your overall efficiency. But many organizations find it tough to implement test standards because they can’t get consensus or changes are met with resistance and push-back from employees.

Test standardization doesn’t have to mean an expensive overhaul of your entire engineering and production test operations. You can implement smaller, more manageable standards, such as code or data management standards that still address and solve inefficiency problems.

While standardizing may be a daunting task, companies who are reluctant to standardizing end up wasting time and money. Without test standards, successful test system solutions aren’t reused or shared between departments. Engineering and production teams may each have specific needs from testing, but standardization is still possible and can positively influence your bottom line.

Before you get caught up on the logistics and potential costs of standardizing your testing, here are 4 benefits that can far outweigh the costs and hassle of implementing standardized test solutions:

1. Test results in the same format as you move from engineering to production

Without a standard format for test data, it’s difficult for your engineering and production departments to share important and valuable findings from testing data. Standardizing data formats allows inter-department communication.

A simple way to do this is to standardize data formats – or at least store data in a defined tagging system. If you chose to continue to have everyone store data in their preferred format, such as text files or spreadsheets, you can build a data abstraction layer to achieve standardization and start sharing your testing data between departments.

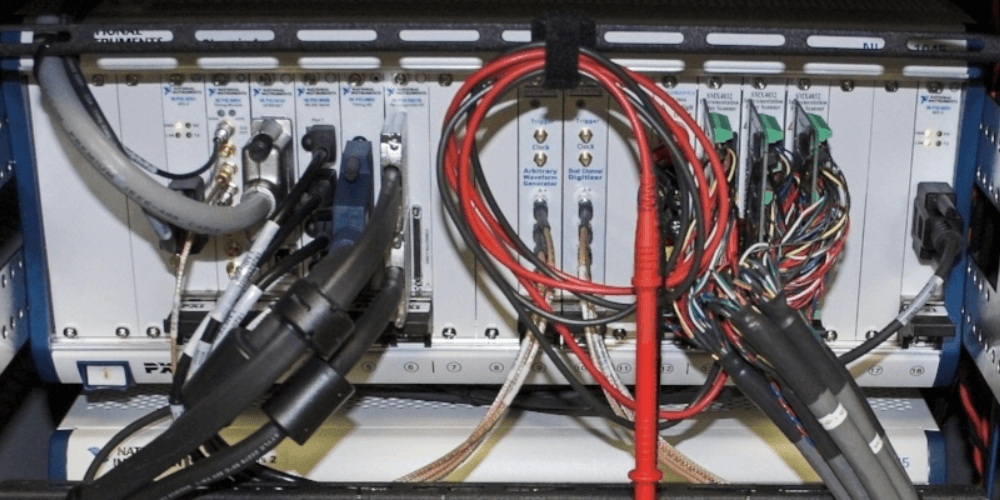

2. Hardware, software, and database reusability

If your company isn’t reusing test solutions in some way, you’re not being as efficient as you could be and creating rework for engineers developing new test systems. Each time your production or engineering test departments need to replace an obsolete test system, valuable time and resources must be spent and wasted on developing a new solution. With test system standards, migrating to a new test system is streamlined because hardware, software and databases can be reused in the design and deployment stages.

3. Cost and time savings

It’s no secret that standardization simplifies your processes, which leads to savings in both time and money. Companies with test standards see reduction in operation costs and downtime events because they are efficiently and progressively solving testing problems through standardization.

With test system standards in place, you can consolidate the time it takes to get a product to market because you aren’t bogged down by designing a completely new test system for each product. You have standards and processes in place to make test system development and deployment faster and easier.

4. Ensure manufacturing quality across production lines and plants

Manufacturing testing is all about bringing quality to your end-users. Without a standard way of testing your products and parts, you can’t ensure product quality. By implementing standards, you can start testing each product or part in the same manner–regardless of what production line or plant the product or part is manufactured at.

Overall, adding test system standards improves overall efficiency for organizations. But standardizing is an overwhelming task and putting it into practice isn’t easy. To standardize and reach these benefits, you must approach standardization the right way.