If you are considering performing tests and acquiring data from a complex, large structure, like a space capsule or aircraft, then you will most likely acquire data from a high-channel count system that has hundreds or even thousands of acquisition channels. A solution designed for less than a hundred channels will not just easily scale by simply adding more channels. There are many considerations beyond just adding more channels when designing, testing, and deploying successful high-channel-count systems. Let’s look at five best practices that you will consider during the design phase of the project and take advantage of throughout the life of the test system.

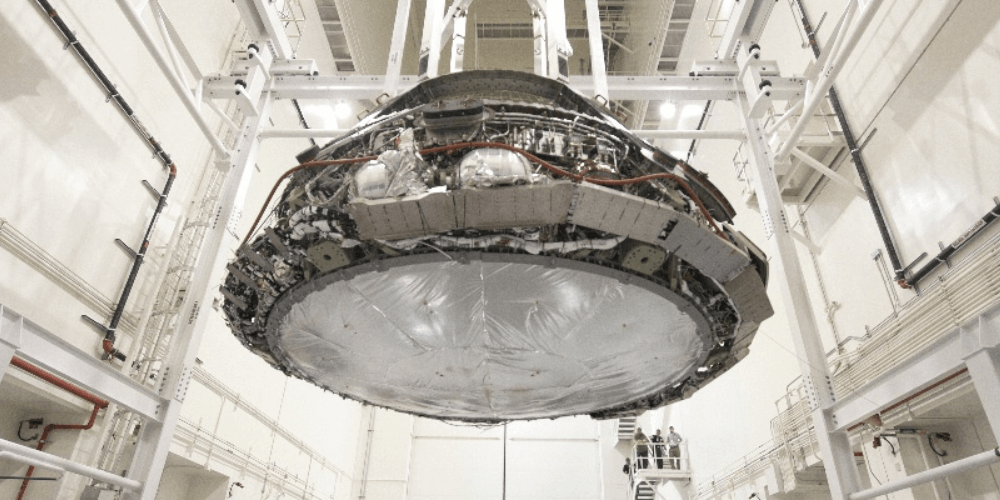

G Systems incorporates these considerations in the high-channel-count systems we create, such as this Orion Structural Test System.

1. Distributed Operation

Oftentimes for a high-channel-count system, numerous components, including servers, clients, and test equipment, are distributed across a facility. The equipment location, data transmission rates, simultaneous processing requirements, interface requirements, and potential safety issues determine how the entire system will be distributed and interconnected. A distributed system is more complicated than a centralized solution but allows for higher overall performance and data availability.

2. Timing and Synchronization

One inherent characteristic of a high-channel-count system is that data is likely coming from multiple data acquisition systems that each have their own time source and potentially their own software application. If you try to make a decision about an event that occurred at a particular moment in time across multiple systems without synchronization your conclusion could be wrong and misleading. Additionally, incorrect timing and synchronization can cause data inaccuracies and lost data. So the question is: how do you guarantee that the data acquired starts at the same time, is correlated, not drifting over time, and is sampled simultaneously? See our white paper for more discussion on this topic.

3. Communication Interfaces

Additionally, these distributed high-channel-count systems need to pass data between each other. When evaluating which communication protocol or interface to select, consider compatibility, throughput, reliability, fault tolerance, scalability, and accessibility. Based on these considerations, you can then select from standard or advanced network communications protocols or a dedicated physical connection.

4. System Configuration

Each channel in a high-channel-count system usually has multiple settings and configurations, including scale factors or alarm limits, that might need to change based on a test setup. Configuring thousands of channels can be time consuming and error prone if it is done manually one channel at a time. Also, any time a setting is changed, the results are directly impacted. Thus, tracking changes and limiting who can make modifications to the configuration is very important.

5. Self-Calibration and Self-Test

Each data acquisition module is typically calibrated by the manufacturer. However, this calibration does not take into account the entire measurement path from sensor through signal conditioning and ending in the analog-to-digital conversion. Therefore, automating the verification of end-to-end measurement path calibration is a tremendous cost and time saver over the entire life of the test system.

In high channel-count system, improper design decisions and implementation can lead to low performance, inaccurate data, and lost time and money. Thus, it is important to pick a system integrator who has a proven track record of using best practices that address these concerns, such as G Systems, who has designed high channel-count systems for more than 25 years.

Learn more these best practices and see how G Systems has implemented them into real-world applications by downloading this white paper.