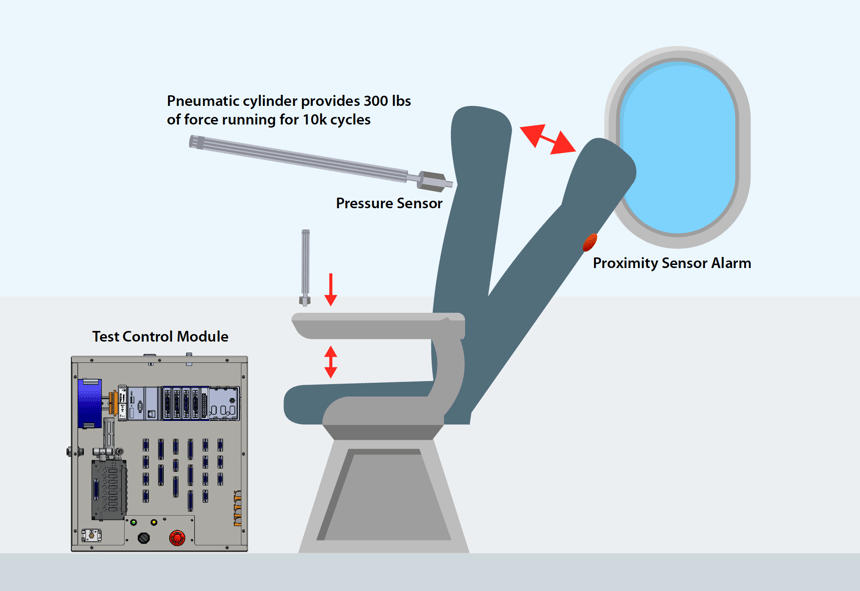

To ensure the functionality and safety of its aircraft seats, Recaro Aircraft Seating, a leading global aircraft seat manufacturer, needs to perform numerous life cycle tests. Each life cycle test requires specific setup conditions and various instruments and actuators to simulate a lifetime of wear and tear inflicted on aircraft seats.

Initially, Recaro outsourced its life cycle testing to an independent lab. To create a more streamlined test process, Recaro wanted to bring its testing into a single in-house system. Working closely with Recaro, we developed a fully scalable hardware and software solution that can run continuously and reliably for weeks.

This flexible, universal control platform consists of modular hardware and real-time control software. Because the new test system is modular, it can be easily configured to run multiple test conditions using a variety of sensors and test limits. The system has been in service for nine years, and recently, we implemented a multi-thread upgrade that allows the system to perform up to four different tests simultaneously, greatly improving Recaro’s throughput.

Additionally, the system software is simple to maintain and highly intuitive; it can be operated by both technicians and engineers. Users can configure tests and view data in real time through a custom graphical user interface installed on a PC. Recaro engineers also can monitor test progress and, if authorized, pause or cancel tests remotely through a Web-based dashboard.

With the Recaro aircraft seat life cycle test system G Systems developed, Recaro technicians and engineers can complete life cycle testing more rapidly, economically, and reliably. By testing in-house with this new system, Recaro can perform tests reliably for weeks at a time, access test feedback more quickly, and rapidly reconfigure test systems for different seat models.

To learn more about this application, read the full case study.