We recently announced the G Systems Valve Leak Measurement System (VLMS), a low-flow leak detection product that reliably measures slow leaks that are unidentifiable with conventional leak detectors. This system is already helping manufacturers test and ensure that critical valve seals are airtight, and it is perfect for applications that require a zero or near-zero leak rate, including medical devices, pharmaceutical equipment, and oil, gas, and plumbing valves.

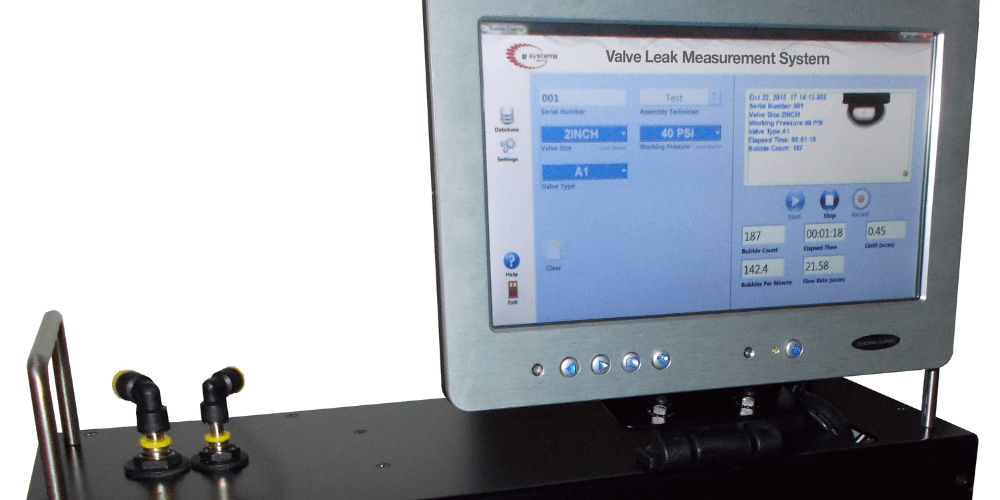

The VLMS includes a simple, touch-screen operator interface for configuration and control of the measurement process. The interface provides bubble count, inferred flow rate, elapsed time, and camera images in real time as the test progresses, and the system stores data for later recall.

Some of the key features include:

- Full integration with any new or existing test fixture and data system

- Wall-mount, bench-top, direct mounting on a machine frame

- USB ports to connect external keyboard/mouse (not required), bar code scanner, or removable storage devices

- API Standard 527 compatibility, Seat Tightness of Pressure Relief Valves

Engineers and technicians use the VLMS in R&D to understand valve capacity and acceleration/deceleration of leaks through continuously monitoring via camera images, and in end-of-line testing, where built-in alerts let them know when the system encounters a leak.

Until now, they had to solve these types of applications with off-the-shelf flow meters, which are not stable at very low flow rates, or rely on the decades-old, industry-accepted practice of counting bubbles formed at the end of a tube submerged in water. This requires a manufacturing line operator to count the number of bubbles that appeared in a specific amount of time in order to quantify the leak rate or verify a zero-leak requirement. These methods are costly, tedious and prone to human error. The VLMS offers an alternative that reduces man-hours and ensures more accurate, automated results.

To learn more about the development of the VLMS, read this case study.