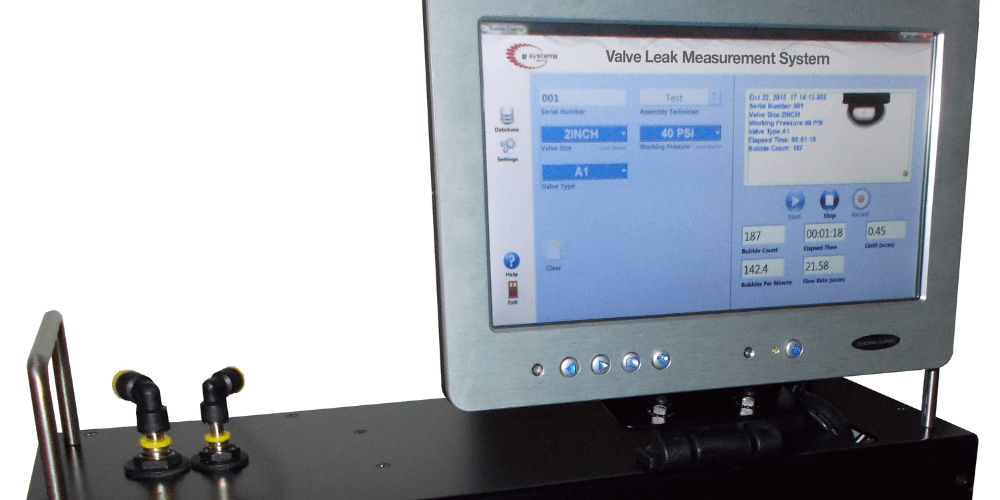

DALLAS, Texas – August 2, 2016 – G Systems, a systems integration firm that designs and builds on-time and on-budget test systems for aerospace, defense, and energy applications, today announced the G Systems Valve Leak Measurement System (VLMS).

“The new low-flow leak detection product reliably measures slow leaks that are unidentifiable with conventional leak detectors, helping manufacturers test and ensure that critical valve seals are acceptable,” said G Systems Vice President of Engineering, Dave Baker. “The automated system provides accurate measurement of leaks too small for conventional flow meters to reliably detect. This reduces critical man-hours for valve testing and ensures more accurate results for our customers – while also providing archived data results from the test.”

The G Systems VLMS is a self-contained counting instrument for automating the industry-standard practice of leak detection by bubble formation using a submerged tube in water. Compatible with API Standard 527, the VLMS is ideal for applications that must have a zero or near-zero leak rate including medical devices, pharmaceutical equipment, and oil, gas, and plumbing valves.

The product includes a simple, touch-screen operator interface for configuration and control of the measurement process. The interface also provides bubble count, inferred flow rate, elapsed time, and camera images in real time as the test progresses, and the system stores data for later recall.

Automated Leak Detection for R&D and End-of-Line Testing

Clients use the low-flow leak detection system from G Systems in R&D applications to understand valve capacity and acceleration/deceleration of leaks by monitoring the application for 24+ hours via camera images.

The G Systems VLMS is also used for end-of-line testing, when engineers take advantage of built-in alerts that occur when the system encounters a bubble. In addition, clients can digitally send test data and images to their customers, ensuring valve validity before a product ships without requiring the customer to travel to the manufacturing site.

G Systems also offers customization services to interface the VLMS software directly to a specific database, or to provide additional real-time information.

G Systems Valve Leak Measurement System (VLMS) Features

- Full integration with any new or existing test fixture and data system

- Installation: wall-mount, bench-top, mounted directly on a machine frame, or portable

- Includes USB ports to connect external keyboard/mouse (not required), bar code scanner, or removable storage devices

- Compatible with API Standard 527, Seat Tightness of Pressure Relief Valves

For more information, visit http://www.gsystems.com/valve-leak-measurement-system.